Alternator Off-Site Repairs

Off-Site Repair

24/7 Alternator Call Out Service.

Keep up and Running

If your alternator can’t be repaired on-site, our team will move it to our fully equipped workshop, where it can be overhauled in a time-frame our rivals just can’t beat.

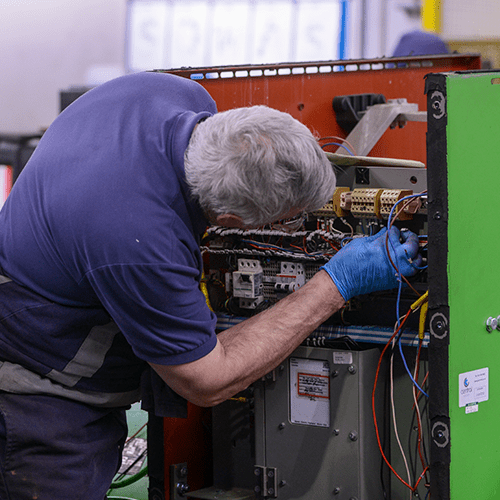

Once the alternator reaches the workshop, our technicians will perform a detailed inspection and diagnosis. They will repair or replace the faulty components, such as brushes, voltage regulator, diodes, or bearings, as necessary.

The repaired alternator will undergo comprehensive testing to ensure its functionality and performance followed by a final inspection, verifying all connections and ensuring that it complies to all the required standards.

Safe in our Hands

Alternators have a number of moving parts, so as they get dirty and are subjected to extreme temperatures. Internal components can wear out, causing the alternator to malfunction.

One of the most common problems you’re likely to experience with an alternator is a failure in the bearings. The coils of alternators are prone to breakages and unwinding. Another problem are the brushes, which are generally made of carbon. They are very fragile and highly susceptible to damage.

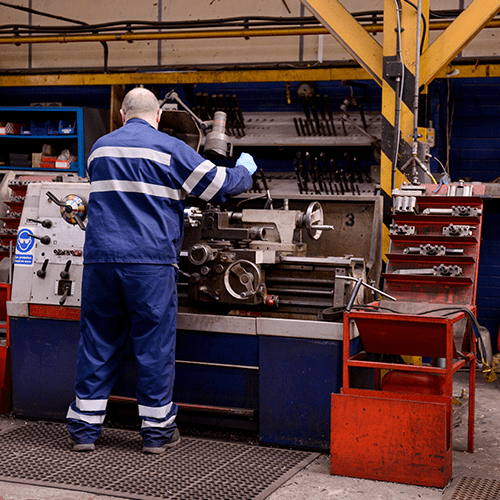

We use our own machine shop and spiral welding facility for mechanical work, and we can rewind to get your alternator back up and running without delay.

Safe in our Hands

Alternators have a number of moving parts, so as they get dirty and are subjected to extreme temperatures. Internal components can wear out, causing the alternator to malfunction.

One of the most common problems you’re likely to experience with an alternator is a failure in the bearings. The coils of alternators are prone to breakages and unwinding. Another problem are the brushes, which are generally made of carbon. They are very fragile and highly susceptible to damage.

We use our own machine shop and spiral welding facility for mechanical work, and we can rewind to get your alternator back up and running without delay.